Hot Forging

Heating the metal using high temperature to shape into the desired form.

Team Work

Manufacturing Cturing Facility/ Process Process

Hot Forging

Heating the metal using high temperature to shape into the desired form.

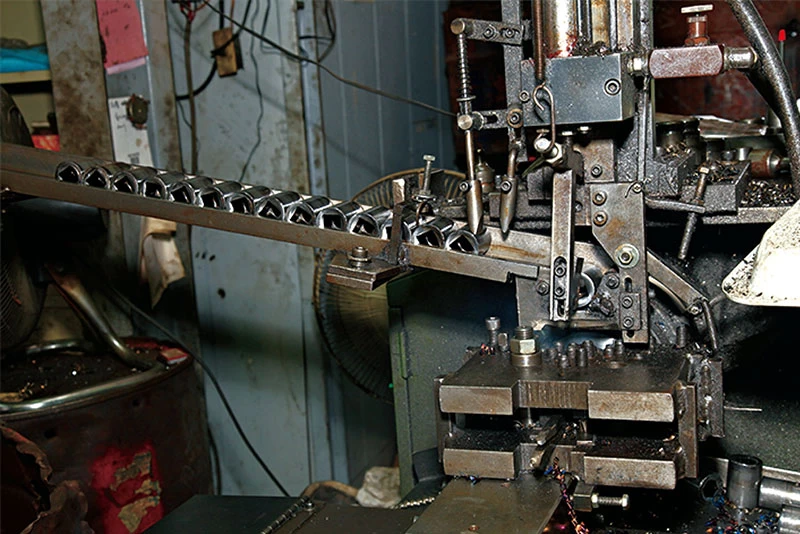

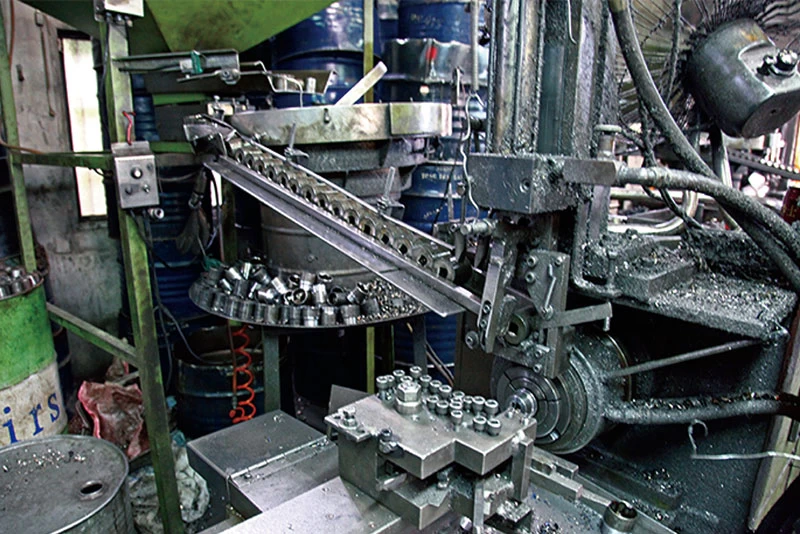

Socket Lathing

A process to achieve the accurate dimension, shape/form of the sockets.

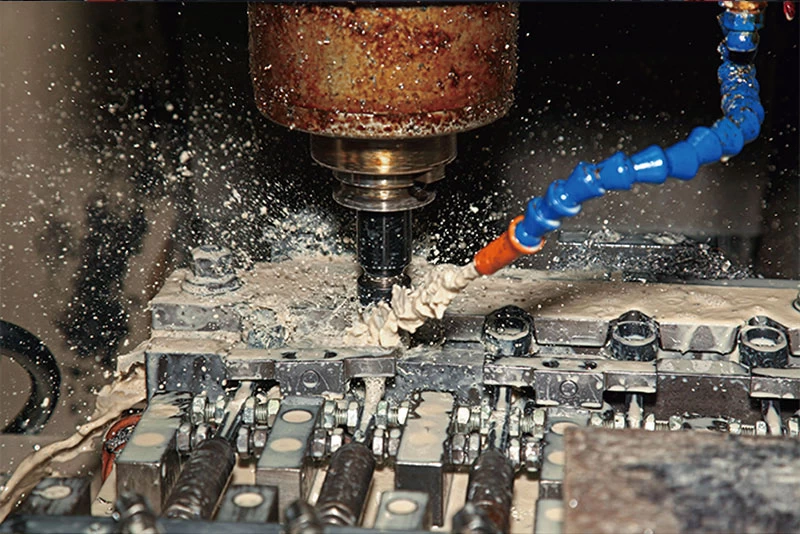

Machining (CNC)~Ratchet, Heavy Duty Sockets, Bit

Used for finishing complicated processes for a better and precise product properties.

Grinding

It is a machining process used to refine the dimensions, shape, or surface finish of sockets and other accessories.

Knurling

A form of procedure to create a pattern such as straight, diamond-shaped ridges that will be embedded to the socket or other accessories for decorative and gripping purposes.

Engraving

Marking tools such as sockets, bits, and other accessories with essential information including size, logo, material composition, and “Made in Taiwan.”

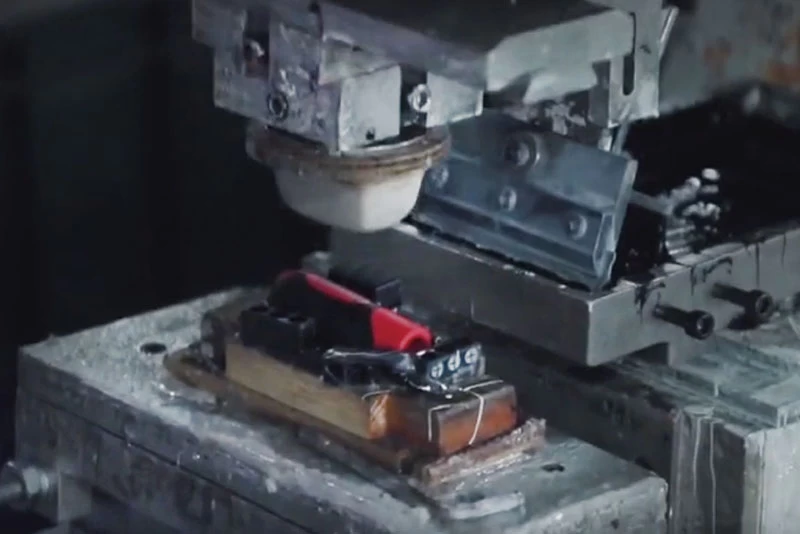

Press Fitting

A method for securely affixing components, such as metal bullets, onto tools such as extension bars, sliding T-bars, adapters, and similar accessories.

Heat Treatment

A procedure of heating and cooling the metal under controlled conditions to achieve desired characteristics like increased hardness, strength, or flexibility.

Vibratory Finishing

A process used to deburr, clean, polish, for a better product.

Sand Blasting

A method to clean or texture the surface of the tools by using an abrasive material such as sand and to remove unwanted coatings.

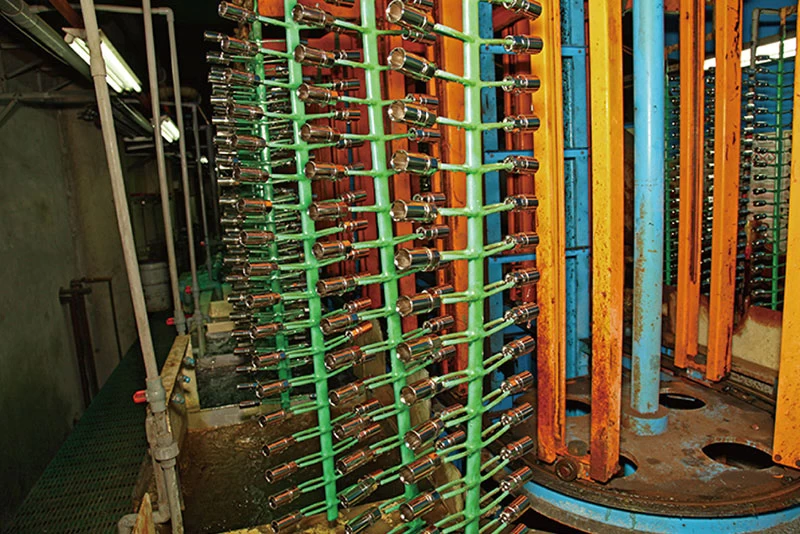

Plating

A method of coating to improve its resistance and surface finish.

Blow Mold Case Molding

Producing blow mold cases through various advanced processes to ensure durability and impeccable design.

Plastic Injection

The production process involves crafting handles and covers for various tools, including screwdrivers, ratchet handles, and more, utilizing high-grade plastic materials for optimal durability and performance.

Laser Marking

Another process of marking tools is through laser printing where it’ll be done digitally for a precise output.

Ratchet Handle Assembly

The process of setting up all the ratchet handle components as well as testing it to ensure optimal functionality.

Printing

This includes printing logo for BMC, metal cases, color ring for sockets, bits, power bits as well as handles for screwdriver and ratchet.

Product Assembly

The stage where packing and finalizing of products takes place.

Storage / Delivery

The place where the semi-processed and the fully finished product are being stored. Also, how the products are prepared for the delivery.